Brand Ambassador

Admissions for the academic year 2026-2027 are now open!

Fifteen years ago, on 120 acres of green land, a dream was born — a dream to change lives through education. It was not just about building classrooms and labs, but about opening doors, creating opportunities, and helping every student grow. This vision came from Thiru K. Shanmugham, who believed that good education should not be only for a few, but for every student, no matter where they come from. In 2010, this vision became reality as the Sri Shanmugha Educational Institutions. Built with courage, care, and a strong mission to uplift society, the institution continues to guide thousands of students to dream big, aim high, and achieve more.

Stories about people, research, and innovation across the campus

Startup Summit

Celebration

Social Service

Guidance Programme

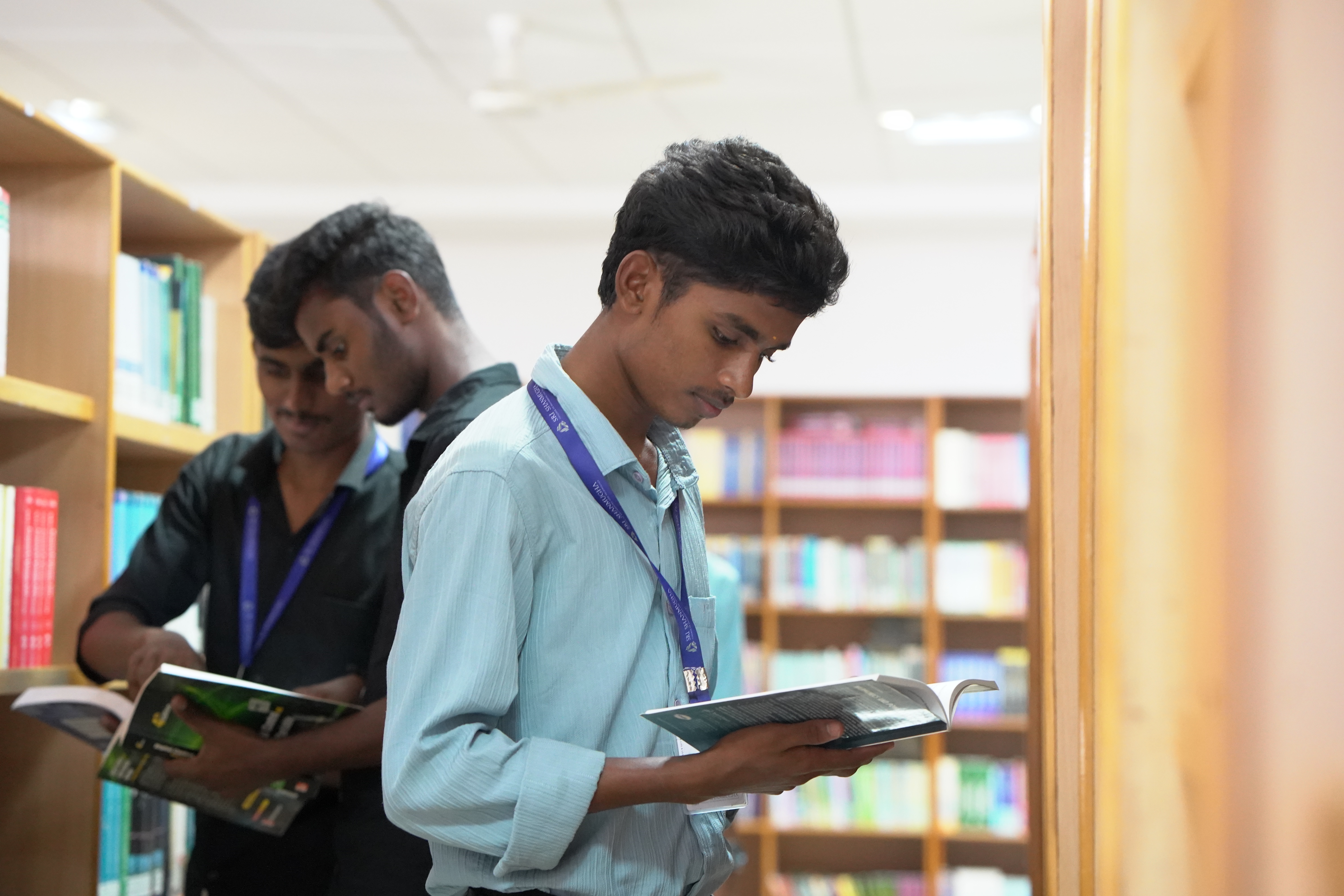

Your gateway to successful careers with industry leaders

Guaranteed job placement for all eligible students

Top MNCs and startups visit for recruitment

Best internship opportunities across industries

Collective amount earned by students through internships

Complete Ecosystem

Continuous Support

Connecting students with real-world industry challenges and opportunities.

Strengthening educational foundations through academic partnerships.

Nurturing innovative ideas into successful ventures and startups.

Fostering creative thinking and breakthrough technological solutions.

Providing hands-on experience through structured internship programs.

Fast-track your startup journey with our comprehensive acceleration program and mentorship.

Access seed funding, investor networks, and financial planning assistance for your venture.

Connect with 21+ expert mentors from various industries for guidance and support.

Test and validate your business ideas with real market feedback and data analysis.

Participate in ideation sessions, design thinking workshops, and innovation challenges.

Develop effective strategies to launch and scale your product in the market.