Sri Shanmugha Educational Institutions

- ABOUT THE DEPARTMENT

- FACULTY PROFILE

- VISION & MISSION

- PO, PEO & PSO

- CURRICULUM & SYLLABI

- BOS Meeting

- DEPARTMENT ACADEMIC CALENDAR

- RESEARCH & CONSULTANCY

- LIBRARY DETAILS

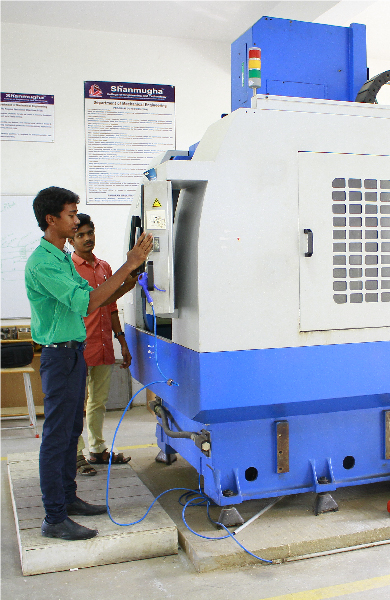

- LABORATORY FACILITIES

- STUDENT PARTICIPATION

- FACULTY PARTICIPATION

- MOU

- INTERNSHIP & INDUSTRIAL VISITS

- PLACEMENT DETAILS

- PROFESSIONAL SOCIETY

- NEWSLETTER

- MAGAZINE

- E-RESOURCES

- EVENT GALLERY

- TESTIMONIALS

Mechanical engineers are constantly pushing the boundaries of what is physically possible in order to produce safer, cheaper, and more efficient machines and mechanical systems. Huge opportunities exist for mechanical engineers and they are being employed in nearly every industry. The department of Mechanical Engineering was established in the year 2011. The department is well poised to shape the students to become highly motivated Scientists, engineers, entrepreneurs, & policy makers needed to address complex societal issues.

- The Department offers Undergraduate program in Mechanical Engineering leading to B.E. degree graduate program

- The department strives to enhance student interests in advances in mechanical engineering, and impart high quality education through well-qualified & highly motivated faculty team, well- equipped laboratories, and instructional facilities

- The department underscores the importance of recognizing that mechanical engineering education must be coupled with modern industry with practices giving hands-on opportunity for every student to relate theory with practice

- The department’s all around sound performance in every sphere of academic activity has a well enough proof that it is student focused

|

1st NBA Accreditation Academic Years 2023-2024 to 2025-2026 (Upto 30.06.2026) |

|

Permanent Affiliation from Anna University Chennai |

|

DEPARTMENT OF MECHANICAL ENGINEERING

| S.NO | NAME OF THE FACULTY MEMBER | DESIGNATION |

| 1 | Dr.N.R.Srinivasan | Professor |

| 2 | Dr.L.Prabu | Associate Professor & Head |

| 3 | Mr.R.Boopathi | Assistant Professor |

| 4 | Mr.M.Mohan | Assistant Professor |

| 5 | Mr.N.Vasantha Prasath | Assistant Professor |

| 6 | Mr.V.Kavinraj | Assistant Professor |

| 7 | Mr.E.Gopinath | Assistant Professor |

| 8 | Mr.N.Mugilarasan | Assistant Professor |

| 9 | Mr.A.B.Chandravathanan | Assistant Professor |

| 10 | Mr.D.Arunkumar | Assistant Professor |

| 11 | Mr.T.R.Arunprasand | Assistant Professor |

| 12 | Mr.D.Sakthivel | Assistant Professor |

| Faculty Details |  |

|

| Name of Faculty | Dr.N.R.Srinivasan | |

| Designation | Professor | |

| Contact No | 8939741279 | |

| advisor@shanmugha.edu.in | ||

| Qualification | M.Tech.,Ph.D., | |

| Specialization | Nanoparticle, Composite, Heat Transfer, Mathematical Modeling | |

| Experience (in years) | ||

| Teaching | 18Years 3 Months | |

| Industry | 4 Years | |

| Faculty Details |  |

|

| Name of Faculty | Dr.L.Prabu | |

| Designation | Associate Professor & Head | |

| Contact No | 9894717464 | |

| hod.mech@shanmugha.edu.in | ||

| Qualification | M.E.,Ph.D., | |

| Specialization | CAD | |

| Experience (in years) | ||

| Teaching | 14 Years 3 Months | |

| Industry | 2 Years | |

| Faculty Details |  |

|

| Name of Faculty | Mr.R.Boopathi | |

| Designation | Assistant Professor | |

| Contact No | 7402157537 | |

| boopathi.mech@shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Thermal Engineering | |

| Experience (in years) | ||

| Teaching | 14 Years 6 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.M.Mohan | |

| Designation | Assistant Professor | |

| Contact No | 9600257003 | |

| mohan.mech@shanmugha.edu.in | ||

| Qualification | M.E | |

| Specialization | CAD CAM | |

| Experience (in years) | ||

| Teaching | 12 Years 0 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.N.Vasantha Prasath | |

| Designation | Assistant Professor | |

| Contact No | 9361311104 | |

| Vasanthaprasath.n@shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Manufacturing System | |

| Experience (in years) | ||

| Teaching | 12 Years 9 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.V.Kavin Raj | |

| Designation | Assistant Professor | |

| Contact No | 9566979886 | |

| kavinraj@shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Engineering Design | |

| Experience (in years) | ||

| Teaching | 12 Years 5 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.E.Gopinath | |

| Designation | Assistant Professor | |

| Contact No | 9865637945 | |

| gopinath619@ shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Manufacturing | |

| Experience (in years) | ||

| Teaching | 9 Years 2 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.N.Mugilarasan | |

| Designation | Assistant Professor | |

| Contact No | 9043658882 | |

| mugilnag.111@ shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Thermal Engineering | |

| Experience (in years) | ||

| Teaching | 7 Years 8 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | A.B.Chandravathanan | |

| Designation | Assistant Professor | |

| Contact No | 9788618244 | |

| chandravathanan@shanmugha.edu.in | ||

| Qualification | M.E | |

| Specialization | CAD | |

| Experience (in years) | ||

| Teaching | 11 Years | |

| Industry | 0.6 months | |

| Faculty Details |  |

|

| Name of Faculty | Mr.D.Arunkumar | |

| Designation | Assistant Professor | |

| Contact No | 8610087432 | |

| arunkumard@shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Engineering Design | |

| Experience (in years) | ||

| Teaching | 2 Years 8 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.T.R.Arunprasand | |

| Designation | Assistant Professor | |

| Contact No | 8300256246 | |

| arunprasand.ir@ shanmugha.edu.in | ||

| Qualification | M.E.,(Ph.D)., | |

| Specialization | Engineering Design | |

| Experience (in years) | ||

| Teaching | 2 Years 8 Months | |

| Industry | – | |

| Faculty Details |  |

|

| Name of Faculty | Mr.D.Sakthivel | |

| Designation | Assistant Professor | |

| Contact No | 9655965232 | |

| sakthivelmech2010@ shanmugha.edu.in | ||

| Qualification | M.E., | |

| Specialization | Industrial safety Engineering | |

| Experience (in years) | ||

| Teaching | 8 Months | |

| Industry | – | |

Vision

To prepare competent mechanical engineers capable of working in an interdisciplinary environment contributing to society through innovation, leadership and entrepreneurship

Mission

M1:To offer quality education which enables them in professional practice and career

M2: To provide learning opportunities in the state-of-the-art research facilities to create, interpret, apply and disseminate knowledge in their profession

M3:To prepare the students as professional engineers in the society with an awareness of environmental and ethical values

Programme Outcomes (POs)

Students of Mechanical engineering programme should at the time of their graduation be in possession of

- Engineering knowledge:Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems

- Problem analysis:Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

- Design/development of solutions:Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations

- Conduct investigations of complex problems:Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

- Modern tool usage:Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations

- The engineer and society:Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice

- Environment and sustainability:Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

- Ethics:Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice

- Individual and team work:Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

- Communication:Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions

- Project management and finance:Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments

- Life-long learning:Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Program Specific Outcomes (PSOs)

- PSO1:Modelling, Simulation and Analysis in the field of Manufacturing

- PSO2:Develop and implement new ideas on product design with help of modern CAD tools

Program Educational Objectives (PEOs)

PEO1: To prepare students to take up career in Industry, Academia as well as in Public service

PEO2 : To provide core domain and interpersonal skills to design & develop mechanical systems for interdisciplinary applications following ethical code

PEO3 : To develop qualities to progress in entrepreneurship and research activities

Research paper format

2024

| N.R. Srinivasan, Shaymaa Al-Rubaye, Chandrasekar M Subramaniyam, “Structural properties and electrochemical performances of mesoporous carbon towards enhanced lithium-ion storage” , Chemistry of Inorganic Materials. 2, 2024, 100032 |

|

Raja Selvaraj, Sanjana Jogi, Gokulakrishnan Murugesan, N.R. Srinivasan, Louella Concepta Goveas, Thivaharan Varadavenkatesan , Adithya Samanth, Ramesh Vinayagam, Mohammed Ali Alshehri, Arivalagan Pugazhendhi “Machine learning and statistical physics modeling of tetracycline adsorption using activated carbon derived from Cynometra ramiflora fruit biomass” 252,2, 2024, 118816 |

2023

| Karuppanan Kalimuthu, N. R. Srinivasan,G.Govindarajan, “Antibiotic‐Peptide Conjugation Against Multi‐drug Resistant

Pathogens: A Comprehensive Review for Therapeutics and Drug Delivery Strategies” , International Journal of Peptide Research and Therapeutics, Volume29.NO.91, September-2023.Impact Factor:2.5

|

| T. Sathies, M. Kumaran, G. Bharathiraja, N.S. Balaji, T.G. Unnikrishnan, V. Senthil Kumar,Investigations on the effect of heat treatment on laser powder bed fusion built SS316L alloy,Materials Today: Proceedings,Volume 62, Part 8,2022,Pages 5411-5414, Impact Factor:3.5 |

2022

| Kumaran, V. Senthilkumar, T. Sathies, C.T. Justus Panicker,Effect of heat treatment on stainless steel 316L alloy sandwich structure fabricated using directed energy deposition and powder bed fusion,Materials Letters,Volume 313,2022,131766, Impact Factor:3.5 |

| E. Gopinath,Experimental study on silica sand using bottom ash on metal casting,Materials Today: Proceedings,Volume 46, Part 10,

2021,Pages 4884-4891, Impact Factor:3.5 |

2021

| R. Boopathi, E. Gopinath,Performance analysis of plastic oil blend by changing the fuel injection timing in diesel engine,Materials Today: Proceedings,Volume 46, Part 10,2021,Pages 4613-4618,Impact Factor:3.5 |

| D. Raghulnath, K. Saravanan, J. Mahendran, M. Ranjith kumar, P. Lakshmanan,Analysis and optimization of organic Rankine cycle for IC engine waste heat recovery system,Materials Today: Proceedings,Volume 21, Part 1,2020,Pages 30-35, Impact Factor:3.5 |

| J. Mahendran, K. Saravanan, D. Ragulnath,Performance and emission characteristics of algae derived biodiesel processes,Materials Today: Proceedings,Volume 21, Part 1,2020,Pages 268-271, Impact Factor:3.5 |

| J. Mahendran,Experimental analysis of shell and tube heat exchanger using flower baffle plate configuration,Materials Today: Proceedings,Volume 21, Part 1,2020,Pages 419-424, Impact Factor:3.5 |

Conference Proceedings

2022-23

| 1. “Structural analysis of base frame of stone collector attachment for tractor” in the 2nd International virtual conference on “Advances in automobile, manufacturing and mechanical engineering” (ICAAMME’23) at Easwari Engineering College,Chennai , India, held on 28 April 2023. ISBN: 978-93-94412-16-3 |

| 2. “Biodiesel production from goat fat waste and analyzing performance of various blends” in the National conference on engineering applications of alternate fuels, sustainable energy and bio-materials, Annamalai University, India |

| 3. “Feasibility study of natural fiber reinforced composite materials for truck body building application” in the 2nd International virtual conference on “Advances in automobile, manufacturing and mechanical engineering” (ICAAMME’23) at Easwari Engineering College,Chennai , India, held on 28 April 2023. ISBN: 978-93-94412-16-3 |

| 4. “Optimization of ventilation for e-bike battery body cover” in the 2nd International virtual conference on “Advances in automobile, manufacturing and mechanical engineering” (ICAAMME’23) at Easwari Engineering College, Chennai, India, held on 28 April 2023. ISBN: 978-93-94412-16-3 |

| 5. “Fabrication and Thermal analysis of nanobased pin” in the 2nd International virtual conference on “Advances in automobile, manufacturing and mechanical engineering” (ICAAMME’23) at Easwari Engineering college,Chennai , India, held on 28 April 2023. ISBN: 978-93-94412-16-3 |

| 6. “Structural analysis of fiber reinforced composite material for electronic jacquard machine application” in the 2nd International virtual conference on “Advances in automobile, manufacturing and mechanical engineering” (ICAAMME’23) at Easwari Engineering college,Chennai , India, held on 28 April 2023. ISBN: 978-93-94412-16-3 |

2021-22

| 1. “Performance and emission characteristics of CRDI Engine using diesel and waste cooking oil ” in the National conference on Advances in Mechanical Sciences(AIMS2022), Mahendra Institute of Technology, India |

2020-21

| 1. “Design and analysis of foldable battery lifter” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 2. “Design and analysis of modified tube in shell and tube heat exchanger” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 3. “Design and analysis of hybrid propeller shaft with modified alignment ” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 4. “Design and analysis of leaf spring for light weight vehicles ” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 5. “Determination of mechanical properties of intra layer jute glass fiber reinforced composite” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 6. “Evaluation of mechanical properties of flax jute glass fiber reinforced composite” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 7. “Natural convective heat transfer from inclined narrow plates” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

| 8. “Design and analysis of Bailing machine” in the 23rd Annual engineering staff convention of ISTE Tamilnadu section , ISTE&Muthayammal Engineering College, India |

Patent Details

| S.No | Title | Inventors/ Applicants Name | Application Number | Status |

| 1 |

Integrated Stone Collector attachment with Chisel Plough DOF: 17/05/2023 |

Dr.L.Prabu et.al | 49443 / 202341034622 | Filed |

| 2 | Biodiesel production from goat fat oil using NaOH catalyst

DOF: 17/05/2023 |

Mr.R.Boopathi et.al | 202341033943 | Filed |

| 3 | Multipurpose tilt able electric trolley DOF: 15/07/2023 | Dr.L.Prabu et.al | 390378-001 | Granted |

| 4 | E-Bike body cover assembly

DOF: 01/02/2023 |

Dr.L.Prabu et.al | 378361-001 | Granted |

| 5 | E-Bike fins integrated battery mount stand

DOF: 01/02/2023 |

Dr.L.Prabu et.al | 378361-001 | Received First Examination Report(Response Submitted) |

| 6 | Autonomous fluid dispersion system

DOF: 31/05/2023 |

Dr.L.Prabu et.al | 387402-001 | Granted |

| 7 | Minimum quantity fluid dispersion system

DOF: 31/05/2023 |

Dr.L.Prabu et.al | 387397-001 | Received First Examination Report(Response Submitted) |

| 8 | Gas Cylinder Trolley

DOF: 31/05/2023 |

Dr.L.Prabu et.al | 387391-001 | Received First Examination Report(Response Submitted) |

| 9 | Tool and die design of Retrofit type electric bike bodycover

DOF: 31/05/2023 |

Dr.L.Prabu et.al | 387393-001 | Received First Examination Report(Response Submitted) |

| 10 | Electronic module pin lifting rod

DOF: 31/05/2023 |

Dr.L.Prabu et.al | 386754-001 | Granted |

| 11 | Retrofit type electric bike body cover

DOF: 31/05/2023 |

Dr.L.Prabu et.al | 387395-001 | Granted |

Book Chapter

| S.No | Author Name | Title & Book | Publisher | Chapter/

Page No/ Year of Publication |

ISBN/DOI Number |

| 1. |

Book Publications

| S.No | Faculty Name | Title of the Book | Publisher | Year of Publication | ISBN Number |

Sponsored Research

| S.No | Funding Agency with

Sanction Order No |

Project /Proposal Title | Proposal Scheme | Year of Sanction |

Amount/Status

|

Consultancy Projects

| S.No | Funding Agency | Project /Proposal Title | Year of Sanction |

Amount/Status

|

| 1. | Krish Precisions, Tiruchengode

|

Process planning and manufacturing of aerospace components

|

2020-21 | 44825/Completed |

| 2. | Krish Precisions, Tiruchengode

|

Process planning and manufacturing of aerospace components

|

2019-20

|

153164/Completed

|

| 3. | TNSCST | Performance analysis of diesel engine by using plastic oil as an alternative fuel | 2018-19 | 7500/Completed |

| 4. | K.R.Tools Center, Tiruchengode

|

Manufacturing of Rig And Cotter Pin

|

2017-18 | 15164/Completed

|

| 5. | Mold Master Pvt Ltd, Coimbatore | Manufacturing of Aluminium L Bracket

|

2017-18 | 11151/Completed |

| 6. | Mold Master Pvt Ltd, Coimbatore | Manufacturing of Term Nut-03

|

2016-17 | 16052/Completed

|

| 7. | Mold Master Pvt Ltd, Coimbatore | Manufacturing of Term Nut-03& 12

|

2015-16 | 206545/Completed |

| 8. | K.R.Tools Center, Tiruchengode

|

Manufacturing of Rig Cotter Pin

|

2015-16

|

6000/Completed |

| 9. | Mold Master Pvt Ltd, Coimbatore | Manufacturing of Term Nut-03 & 12

|

2014-15 | 215325/Completed |

| S.No. | List of Laboratories |

| 1 | Engineering Practice Laboratory |

| 2 | Computer Aided Drafting and Modeling Laboratory |

| 3 | Fluid Mechanics and Machinery Laboratory |

| 4 | Manufacturing Technology – I laboratory |

| 5 | Strength of Materials Laboratory |

| 6 | Manufacturing Technology – II laboratory |

| 7 | Thermal Engineering Laboratory I |

| 8 | Computer Aided Manufacturing Laboratory |

| 9 | Dynamics of Machinery Laboratory |

| 10 | Metrology and Measurements Laboratory |

| 11 | Heat and Mass Transfer Laboratory |

| 12 | Simulation and Analysis Laboratory |

| 13 | Mechatronics Laboratory |

| 14 | Thermal Engineering Laboratory II |

MANUFACTURING TECHNOLOGY LABORATORY – I

| S.No. | Description of Equipment |

| 1 | Centre Lathes |

| 2 | Horizontal Milling Machine |

| 3 | Vertical Milling Machine |

| 4 | Shaper |

FLUID MECHANICS AND MACHINERY LABORATORY

| S.No. | Description of Equipment |

| 1 | Orifice meter setup |

| 2 | Venturi meter setup |

| 3 | Rotameter setup |

| 4 | Pipe Flow analysis setup |

| 5 | Centrifugal pump/submergible pump setup |

| 6 | Reciprocating pump setup |

| 7 | Gear pump setup |

| 8 | Pelton wheel setup |

| 9 | Francis turbine setup |

| 10 | Kaplan turbine setup |

MANUFACTURING TECHNOLOGY LABORATORY – II

| S.No. | Description of Equipment |

| 1 | Turret and Capstan Lathes (each) |

| 2 | Horizontal Milling Machine |

| 3 | Vertical Milling Machine |

| 4 | Surface Grinding Machine |

| 5 | Cylindrical Grinding Machine |

| 6 | Radial Drilling Machine |

| 7 | lathe Tool Dynamometer |

| 8 | Milling Tool Dynamometer |

| 9 | Gear Hobbling Machine |

| 10 | Tool Makers Microscope |

| 11 | CNC Lathe |

| 12 | CNC milling machine |

| 13 | Gear Shaper machine |

| 14 | Center less grinding machine |

| 15 | Tool and cutter grinder |

THERMAL ENGINEERING LABORATORY – I

| S.No. | Description of Equipment |

| 1 | Two stroke petrol engine cut section model |

| 2 | Four stroke diesel engine cut section model |

| 3 | Red wood viscometer |

| 4 | Apparatus for flash and fire point |

| 5 | 4-stroke Diesel Engine with mechanical loading |

| 6 | 4-stroke Diesel Engine with hydraulic loading |

| 7 | Multi-cylinder Petrol Engine with hydraulic loading |

| 8 | Single cylinder Petrol Engine with electrical loading |

| 9 | Data Acquisition system for 4 stroke diesel engine |

| 10 | Steam Boiler setup with accessories (THERMAX MAKE) |

| 11 | Steam turbine setup |

| 12 | Steam turbine accessories |

| 13 | Four stroke Petrol engine cut section model |

| 14 | Four stroke Four cylinder diesel engine cut section model |

| 15 | Four stroke Four cylinder Petrol engine cut section model |

| 16 | Four stroke Two cylinder diesel engine cut section model |

| 17 | Four stroke 1cylinder diesel engine cut section model (Slow speed) |

| 18 | Cut section model – 4 stroke 4cy Petrol engine with components |

| 19 | Twin cylinder CRDi diesel engine with Electrical loading Test rig. |

STRENGTH OF MATERIALS LABORATORY

| S.No. | Description of Equipment |

| 1 | Analog cum servo universal testing machine |

| 2 | Shear test attachment for UTM |

| 3 | Electronic extensometer |

| 4 | Interface hardware |

| 5 | Extensometer software |

| 6 | Mechanical extensometer |

| 7 | Analog torsion testing machine |

| 8 | Impact testing machine |

| 9 | Vickers hardness testing machine |

| 10 | Rockwell hardness testing machine |

| 11 | Brinell hardness tester |

| 12 | Tensile testing machine with accessories |

| 13 | Deflection test apparatus |

| 14 | Lechatlier apparatus |

| 15 | Vicat apparatus |

| 16 | Mortar cube models |

| 17 | Longitudinal compressometer |

| 18 | Binocular metallurgical microscope |

| 19 | Inverted metallurgical microscope with image analyser |

| 20 | Muffle furnace |

| 21 | 8” double disc variable speed polisher |

DYNAMICS LABORATORY

| S.No. | Description of Equipment |

| 1 | Cam analyser- cam and follower setup with motor apparatus |

| 2 | Motorized Gyroscope apparatus |

| 3 | Universal Governor-Watt,Porter,Proell and Hartnell apparatus |

| 4 | Whirling of shaft |

| 5 | Dynamic balance-Reciprocating setup |

| 6 | Dynamic balance-Rotating apparatus |

| 7 | Static and dynamic balancing apparatus |

| 8 | Vibrating table determination of transmissibility ratio apparatus |

| 9 | Universal vibrating machine- Torsion and Transverse vibration setup |

| 10 | Enlarged gear models and five different model-Spur, Bevel, Warm, Sun and planet, simple and double reduction gear apparatus |

| 11 | Epicyclic gear trains |

| 12 | Slider crank mechanisms |

| 13 | Crank rocker mechanisms |

| 14 | Scotch yoke mechanisms |

| 15 | Quick return mechanisms |

| 16 | Single rotor and double rotor system |

THERMAL ENGINEERING LABORATORY – II

| S.No. | Description of Equipment |

| 1 | Guarded plate apparatus |

| 2 | Lagged pipe apparatus |

| 3 | Natural convection-vertical cylinder apparatus |

| 4 | Forced convection inside tube apparatus |

| 5 | Composite wall apparatus |

| 6 | Thermal conductivity of insulating powder apparatus |

| 7 | Pin-fin apparatus |

| 8 | Stefan-Boltzmann apparatus |

| 9 | Emissivity measurement apparatus |

| 10 | Parallel/counter flow heat exchanger apparatus |

| 11 | Single/two stage reciprocating air compressor |

| 12 | Refrigeration test rig |

| 13 | Air-conditioning test rig |

| 14 | HC Refrigeration system |

| 15 | Fluidized Bed cooling tower |

METROLOGY & MEASUREMENTS LABORATORY

| S.No. | Description of Equipment |

| 1 | Micrometer |

| 2 | Vernier Caliper |

| 3 | Vernier Height Gauge |

| 4 | Vernier depth Gauge |

| 5 | Slip Gauge Set |

| 6 | Gear Tooth Vernier |

| 7 | Sine Bar |

| 8 | Floating Carriage Micrometer |

| 9 | Profile Projector / Tool Makers Microscope |

| 10 | Parallel / counter flow heat exchanger apparatus |

| 11 | Mechanical / Electrical / Pneumatic – Comparator |

| 12 | Autocollimator |

| 13 | Temperature Measuring Setup |

| 14 | Force Measuring Setup |

| 15 | Torque Measuring Setup |

| 16 | Surface finish measuring equipment |

| 17 | Bore gauge |

| 18 | Telescope gauge |

| 19 | Co-ordinate Measuring machine |

CAD/CAM LABORATORY

| S.No. | Description of Equipment |

| 1 | Computer Server |

| 2 | Computer Systems (High end CPU with 4 GB RAM) |

| 3 | A3 size plotter |

| 4 | Laser Printer |

| 5 | CNC Lathe |

| 6 | CNC milling machine |

SIMULATION AND ANALYSIS LABORATORY

| S.No. | Description of Equipment |

| 1 | Computer Work Station |

| 2 | Color Desk Jet Printer |

| 3 | Multibody Dynamic Software Suitable for Mechanism simulation and analysis |

| 4 | C / MATLAB |

MECHATRONICS LABORATORY

| S.No. | Description of Equipment |

| 1 | Basic Pneumatic Trainer Kit with manual and electrical controls/ PLC Control each |

| 2 | Basic Hydraulic Trainer Kit |

| 3 | Hydraulics and Pneumatics Systems Simulation Software |

| 4 | 8051 – Microcontroller kit with stepper motor and drive circuit sets |

| S.No | Name of the Professional Society | No. of Faculty Registered | No. of Students Registered | Total |

| 1 | Society of Automotive Engineers (SAE) | 4 | 40 | 44 |

LIST OF PROFESSIONAL SOCIETY EVENTS CONDUCTED (2023-2024)

| S.No | Name of the Society | Name of the Event | Name of the Guest with Designation and Address | Date | No. of Students Benefited |

| 1 | SAE | Seminar on “Advancement in Farm Machinery” | Er.M.Krishnamurthi

Assistant General manager John Deer Tractors Karnataka |

14.02.2024 | 67 |

| 2 | SAE | Hands on training drone manufacturing | Mr.K.Sathyaselan

Manager Aero-Knotes |

08.07.2023 | 95 |

| 3 | SAE | Farm machinery workshop | Dr.T.Senthilkumar

Principal Scientist RS, ICAR-CIAE |

09.09.2023 | 89 |

| 4 | SAE | Industrial Lecture on “ Design of EV Based Farm Equipments | Dr.E.Ravi

Senior Design Engineer Bull Agro, Coimbatore |

06.12.2023 | 98 |